“Sincerity, Innovation, Rigorousness, and Efficiency” would be the persistent conception of our enterprise with the long-term to establish together with clients for mutual reciprocity and mutual benefit for ODM Manufacturer China Food Grade Grease Milk Transfer Air Operated Diaphragm Pump, Base within the business enterprise concept of Quality to start with, we wish to satisfy more and a lot more good friends within the word and we hope deliver the most beneficial products and support to you.

“Sincerity, Innovation, Rigorousness, and Efficiency” would be the persistent conception of our enterprise with the long-term to establish together with clients for mutual reciprocity and mutual benefit for China Transfer Pump, Liquid Transfer Pump, Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires please do not hesitate to contact us. Thank you – Your support continuously inspires us.

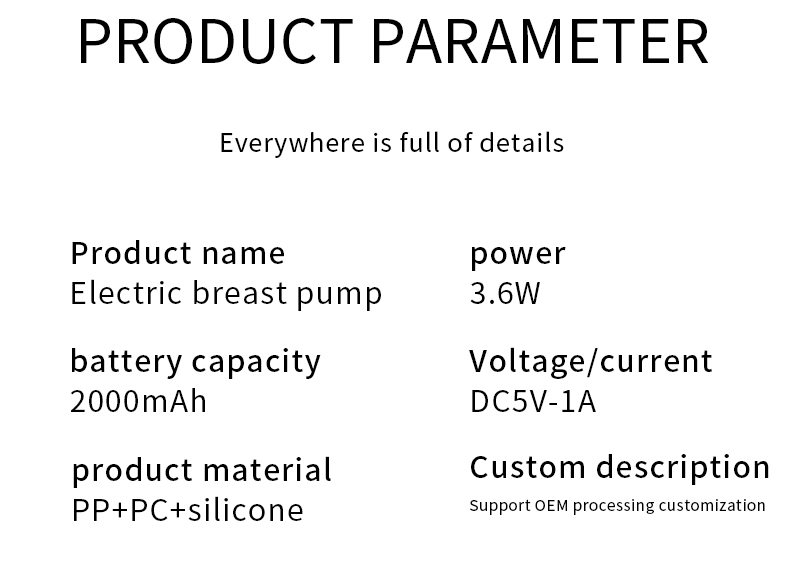

Description:

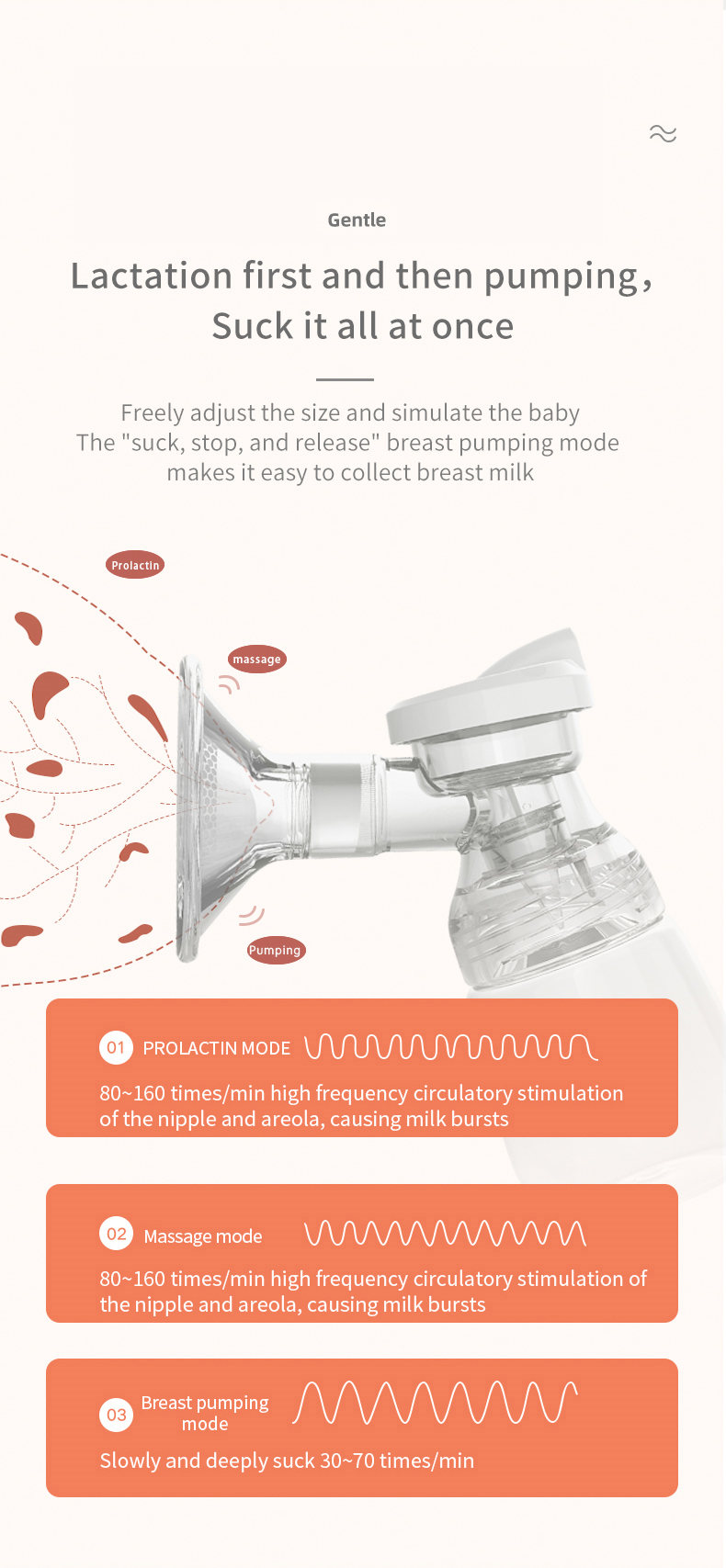

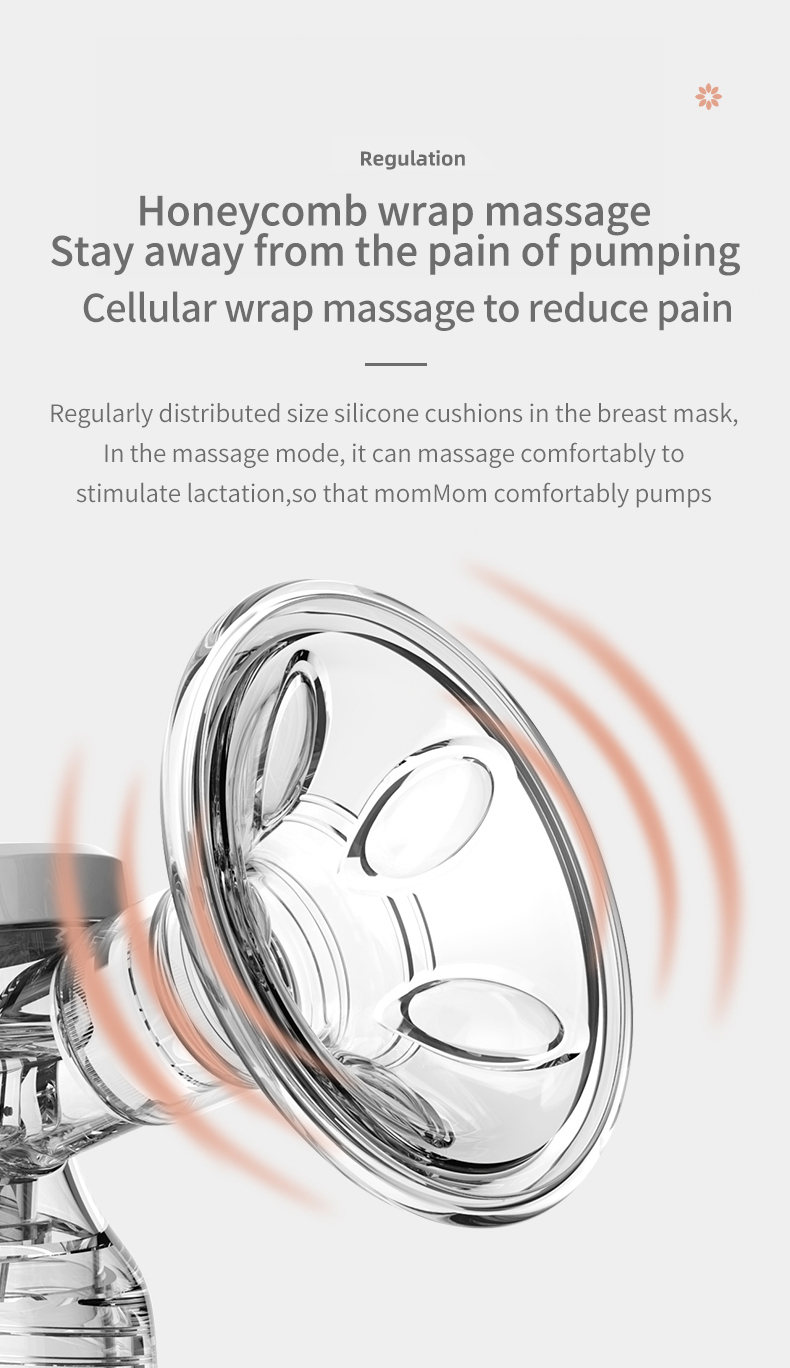

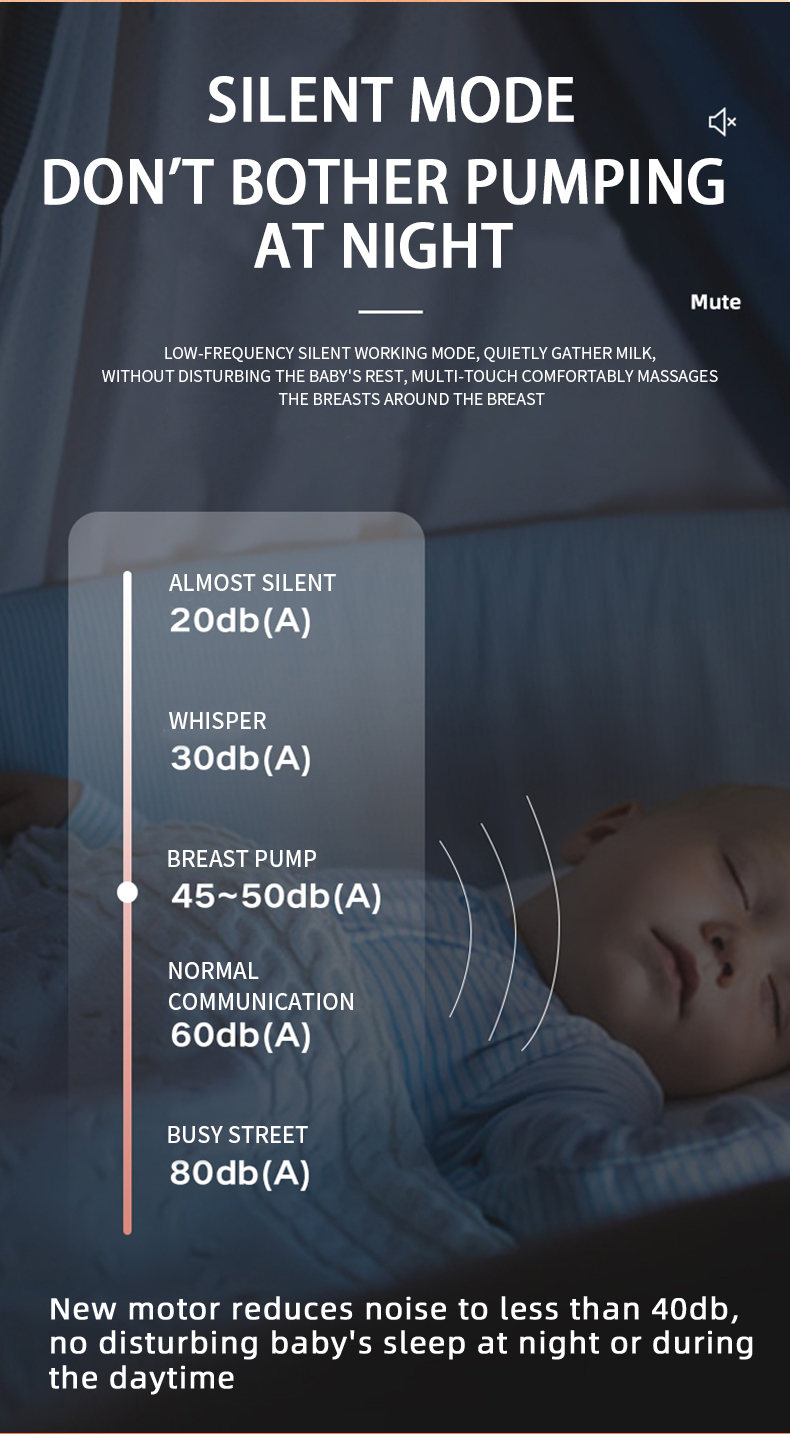

1.Painless milk collect

2.Milk will not flow back

3.The screen is LED

4.With four modes:massage,bionic,pump,stimulation,and nine gears

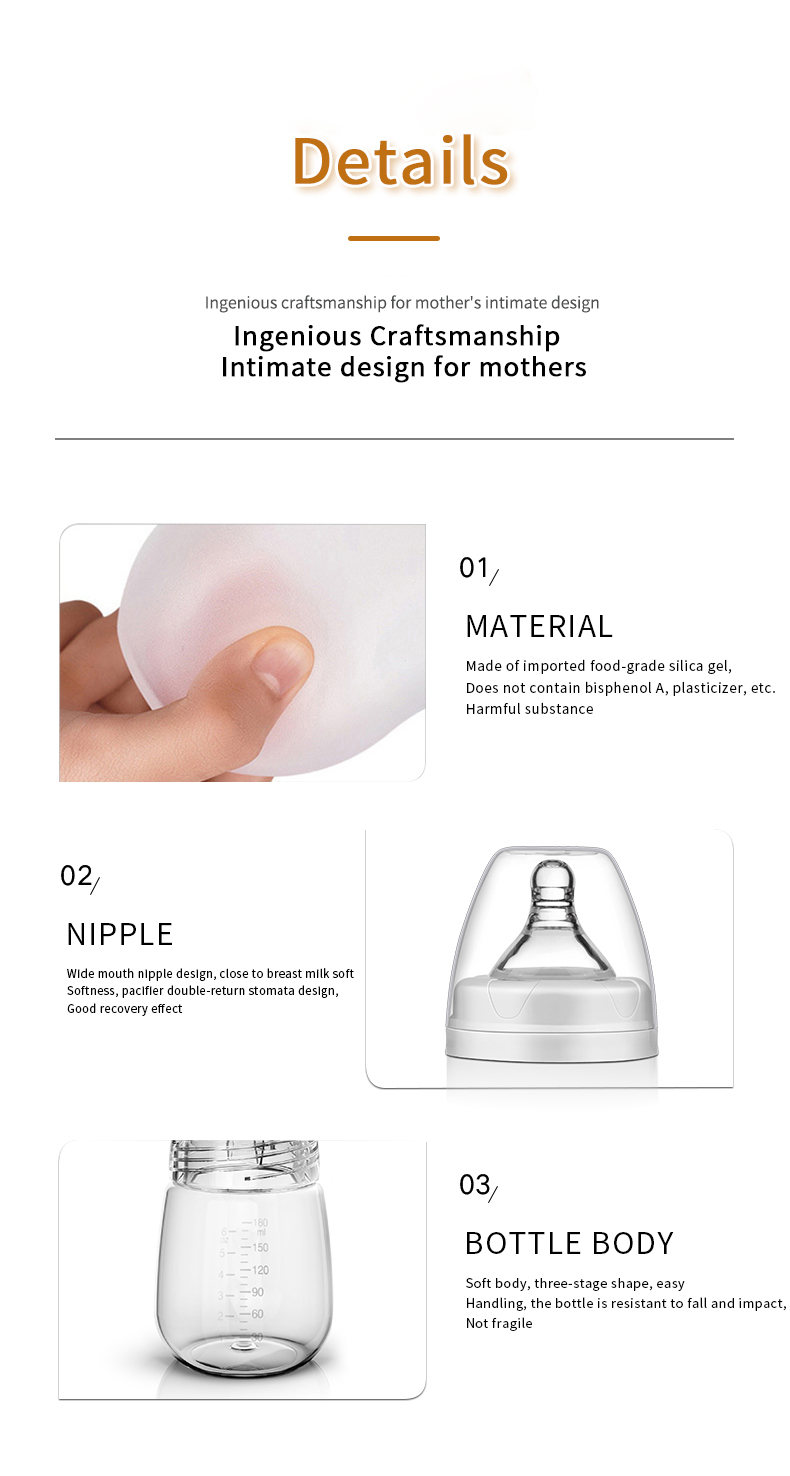

5.PP bottle for food grades

6.1600mAh big lithium battery to support its use on going out without a power adapter.Mother can collect milk wherever they are

7.The control panel with touch design,clear for operation

8.With big battery for going out using or at home

Installation Instructions:

Warm Tip : before each use. should be pre-sterilized with breast milk has direct contact with the components:bottle, silicone horn, three-way silicone cylinder, duck mouth valve, milk bottle cap and so on.

1.Put the silicone horn and bell mouth in sequence, then putin the dust shield.

2.Insert the silicone horn and bell mouth assembly into the three links to ensure that the sleeve is tight.

(Note: when removing, one hand holds the three links, the other hand holds the bell mouth assembly up and woen, gently pull out.)

3.Put the cylinder and cylinder head into three links and tighten the cylinder head.

4.Put the duckbill valve into the bottom outlet of the three-way to ensure that there is no leakage.

5.Screw the three-way assembly into the bottle.

6.Insert the straigt-through joint of the hose into the cylinder head and the relative hole position of the main engine to ensure that there is no air leakage and can be used.

-

Professional China China OEM Automatic Baby USB...

-

DQ-S003BB Breast Pump Meidile Hot Sale Electric...

-

Cheapest Factory China Food Grade Low Noise Ful...

-

OEM/ODM China China Portable Baby Feeding Milk ...

-

OEM Manufacturer China Factory Direct Wholesale...

-

Reasonable price Hospital Food Grade Portable B...